BPS Framework Modeling & Casting

Professional remote BPS framework design in Exocad, high-precision 3D printing, and metal casting. Get premium dental frameworks delivered worldwide with our end-to-end digital workflow.

Our BPS Framework Services

Complete digital workflow from jaw scans to finished metal frameworks with precision and quality control at every step

CAD Framework Design

Professional BPS framework modeling in Exocad Partial CAD V3.3 with precision engineering for optimal fit and function.

Design Features

- Precision modeling in Exocad Partial CAD V3.3

- Optimal framework design for biomechanics

- Customized based on patient anatomy

- Virtual try-in and adjustment

- Technical thickness optimization

- Professional design validation

High-Precision 3D Printing

Advanced 3D printing with Jet Wax 510 printer at 16μm layer resolution for exceptional surface quality and detail.

Printing Advantages

- Jet Wax 510 with 16μm layer resolution

- Superior surface finish quality

- Minimal post-processing required

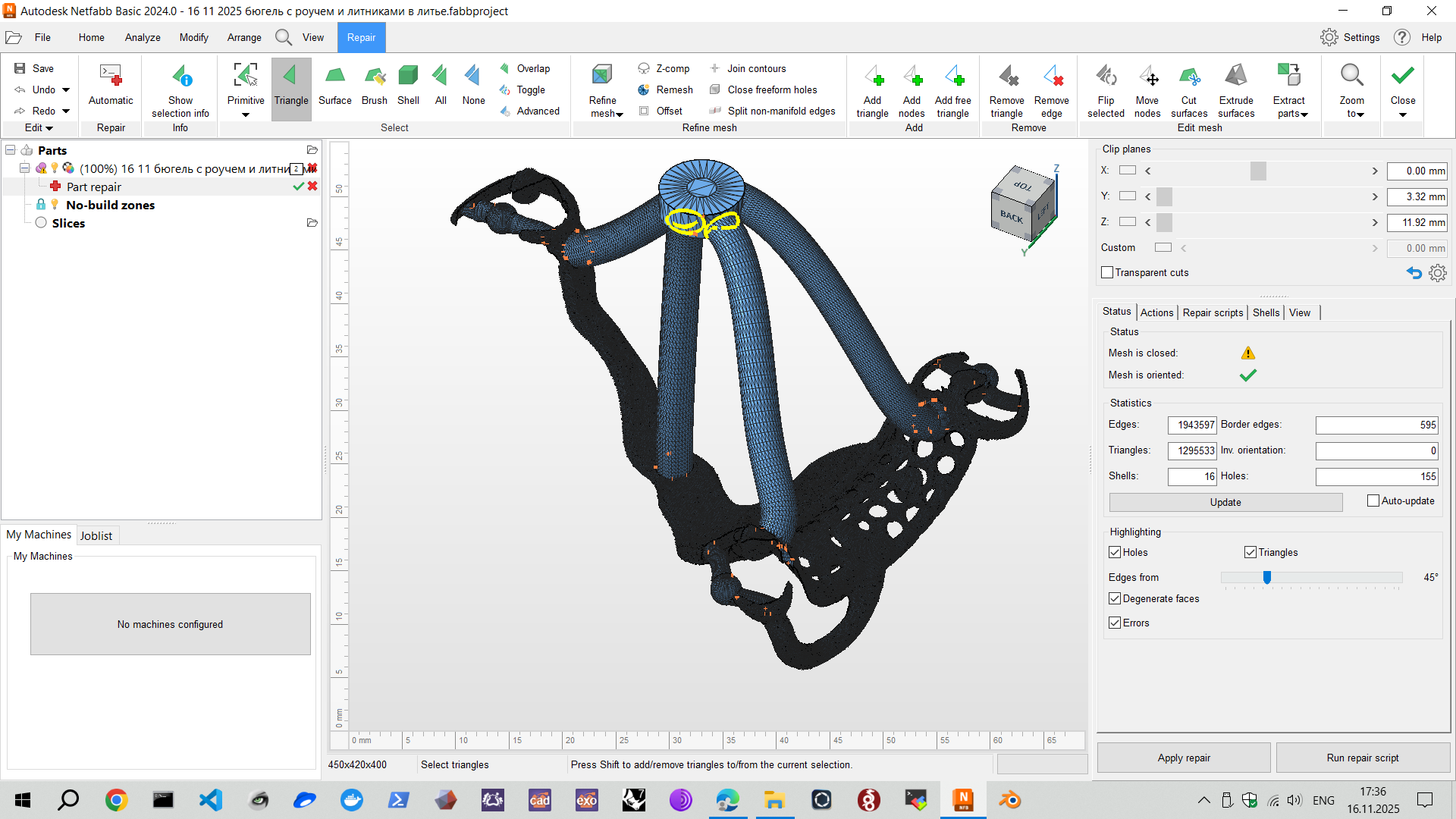

- Precise sprue system design in Blender

- Model preparation in Netfabb & Meshmixer

- Quality control at every stage

Professional Metal Casting

High-quality metal casting in professional foundry with premium alloys and strict quality control standards.

Casting Benefits

- Professional foundry casting

- Premium dental alloys (CoCr, titanium)

- Minimal porosity and defects

- Precision fit guaranteed

- Quality inspection and validation

- Worldwide shipping

Our Digital Workflow Process

Streamlined digital workflow from scan to finished framework with quality control at every step

Digital Impressions

You provide digital scans of the patient's jaw. We accept all major scan file formats for seamless integration.

CAD Framework Design

Precision BPS framework modeling in Exocad with optimal biomechanical design and technical thickness control.

3D Printing

High-resolution printing with Jet Wax 510 at 16μm layer thickness for exceptional detail and surface quality.

Metal Casting

Professional foundry casting with premium dental alloys and strict quality control standards.

Quality Control & Shipping

Comprehensive quality inspection, finishing, and worldwide shipping of the finished framework.

Our Work Gallery

See our precision work from digital design to finished metal frameworks

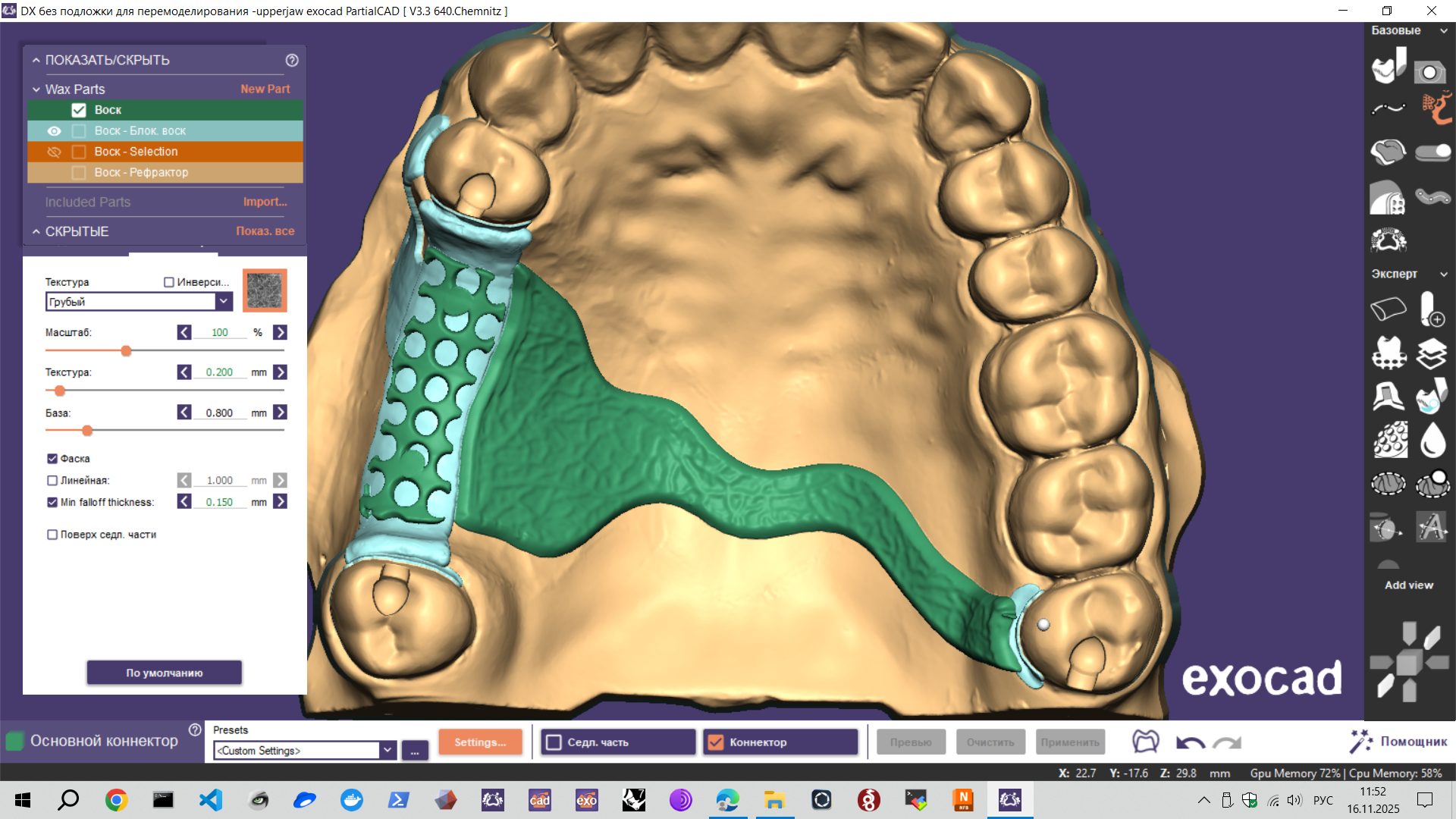

Saddle & Main Connector

Precise modeling of saddle area and main connector in Exocad

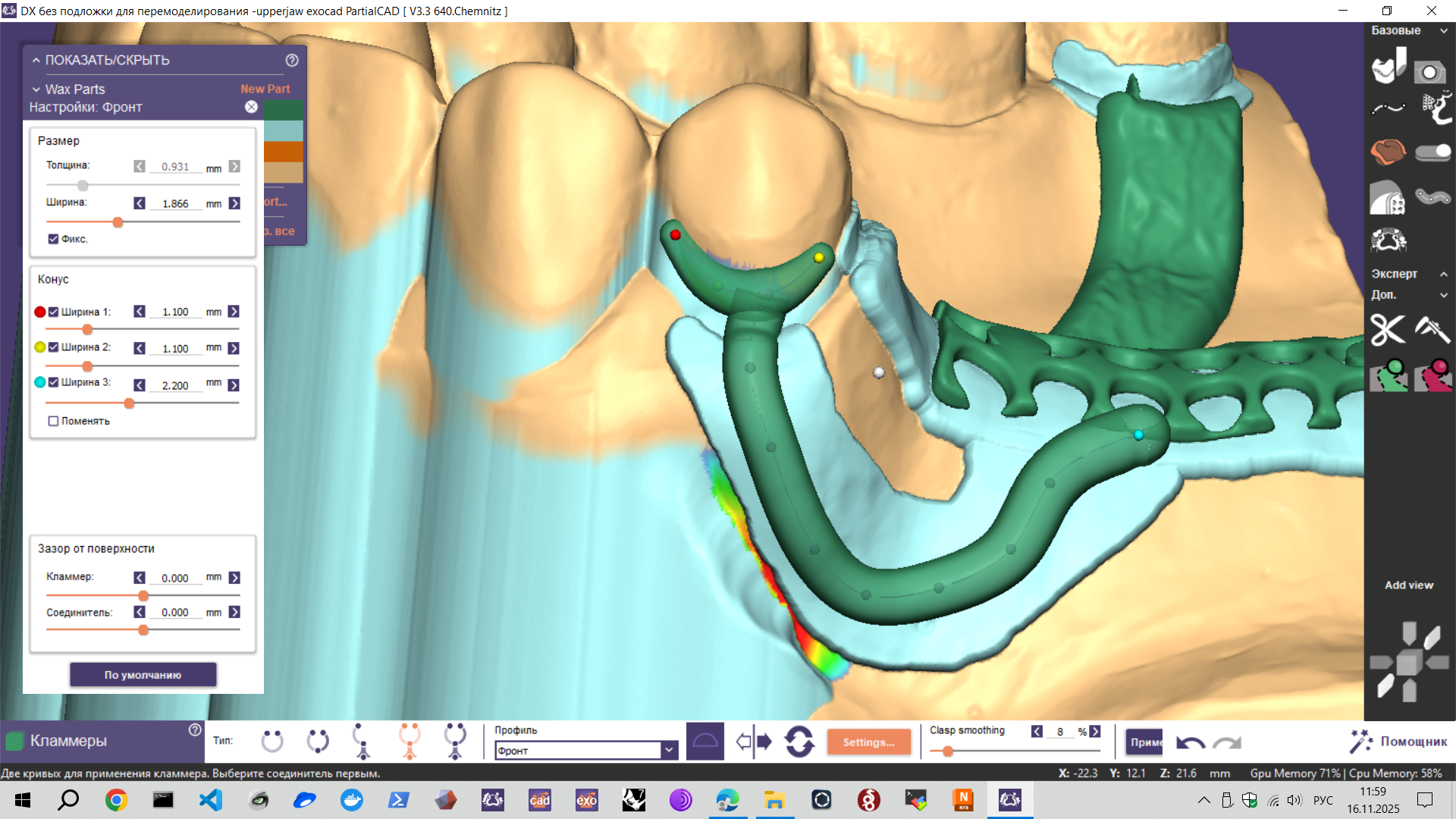

Roach Clasp Design

Designing roach clasp for optimal retention and aesthetics

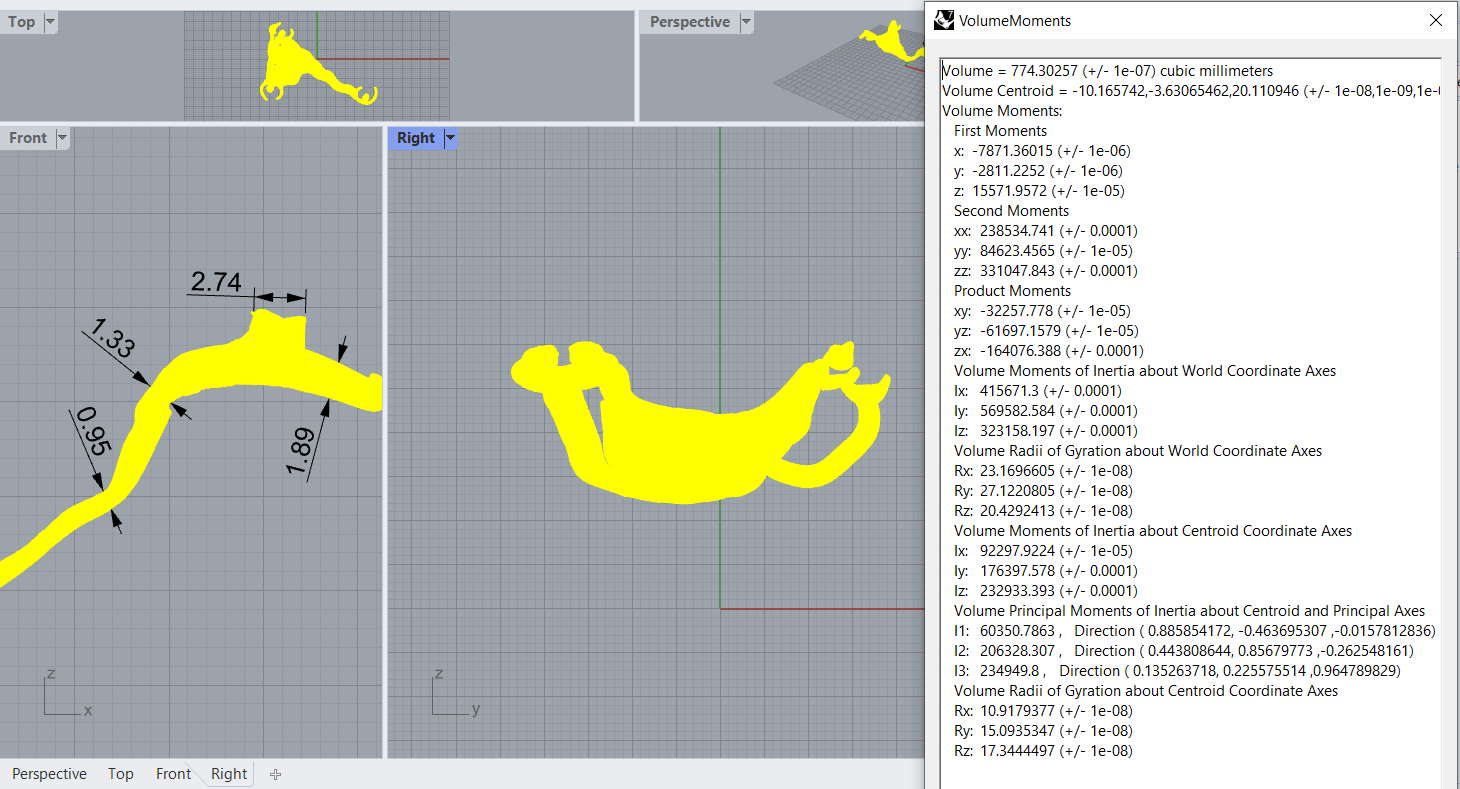

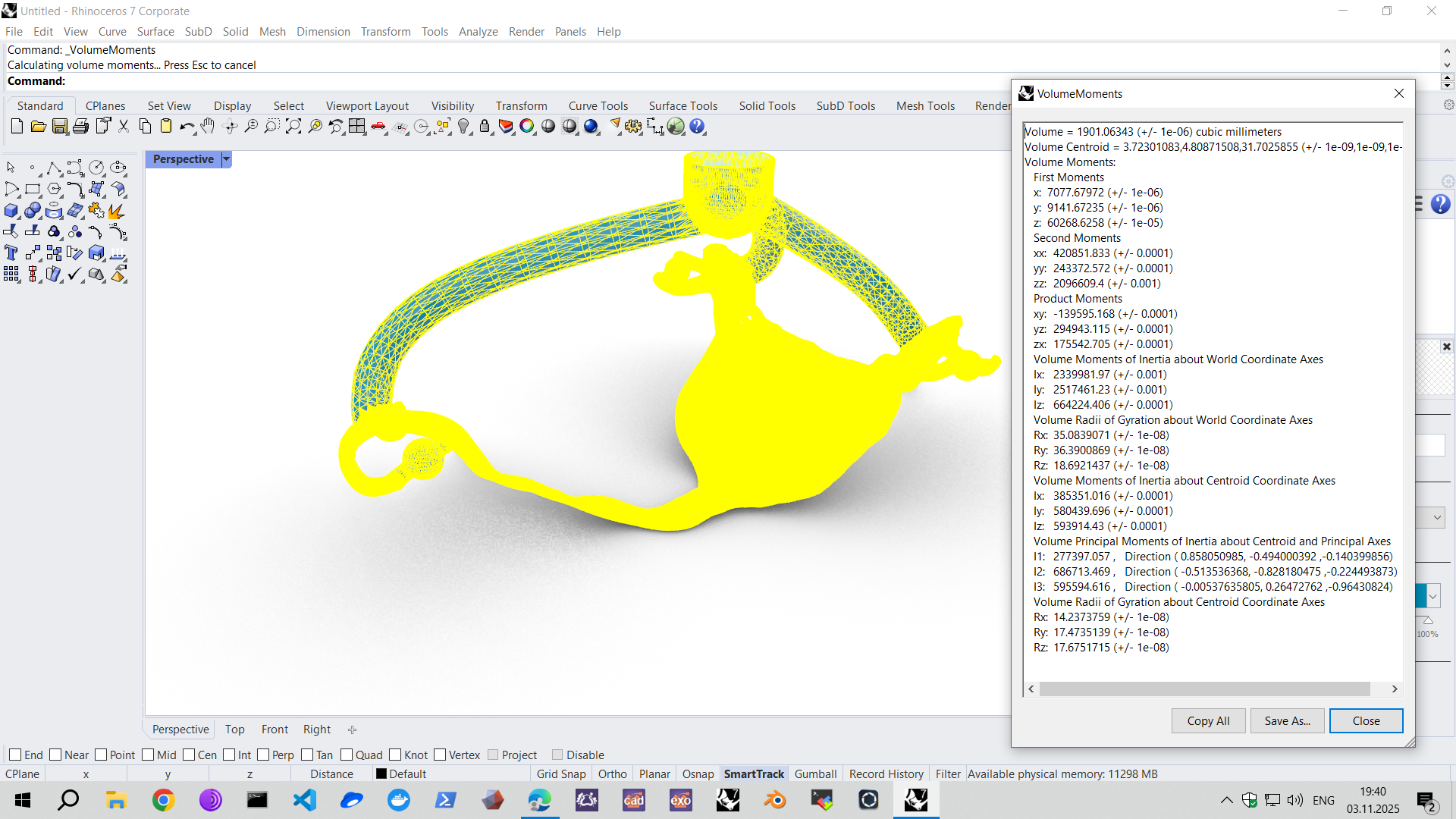

Thickness Verification

Checking framework thickness in Rhinoceros for compliance

Compliance Check

Verifying thickness and pourability requirements for casting

Top View Render

Rendered model from above showing complete framework design

Side View Render

Rendered model from side demonstrating profile and contours

File Preparation

Processing model in Autodesk Netfabb for 3D printing preparation

Wax Model with Sprue

Printed wax model with included casting profit and sprue system

Metal Calculation

Weighing wax model to calculate required metal mass for casting

Casting Profit

Clasp zone with casting profit ensuring proper metal flow

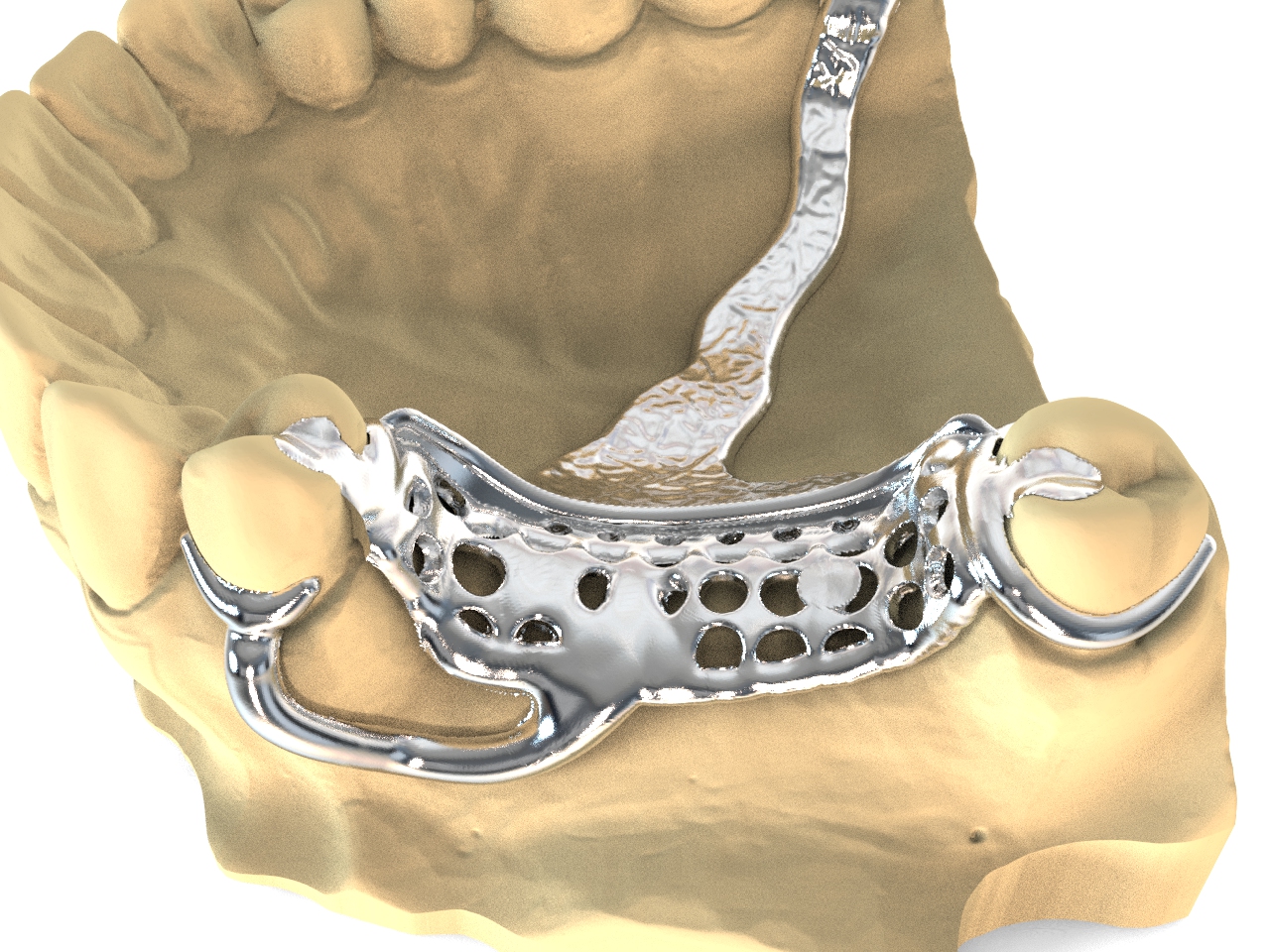

As-Cast Framework

Reverse side of untreated casting showing saddle and connector area

Casting Process

Professional metal casting in progress - photo coming soon

Finished Framework

Completed metal framework ready for polishing - photo coming soon

Our Technical Specifications

Premium equipment and software for exceptional quality and precision

CAD Software

- Primary Design Exocad Partial CAD V3.3

- Sprue Design Blender v5.0

- Model Preparation Autodesk Netfabb Ultimate

- Mesh Editing Meshmixer

3D Printing

- Printer Model Jet Wax 510

- Layer Thickness 16μm (0.016mm)

- Resolution XY: 1200 DPI

- Material Castable Dental Wax

Casting Process

- Alloys CoCr, Titanium

- Casting Method Centrifugal Casting

- Porosity Control Pressure/Vacuum

- Quality Standard ISO 13485

Framework Thickness Specifications

| Framework Component | Minimum Thickness | Optimal Thickness | Maximum Thickness | Notes |

|---|---|---|---|---|

| Major Connector | 0.8 mm | 1.0 - 1.2 mm | 1.5 mm | Uniform thickness for rigidity |

| Minor Connector | 0.7 mm | 0.8 - 1.0 mm | 1.2 mm | Sufficient for stress distribution |

| Clasp Arms | 0.6 mm | 0.8 - 1.0 mm | 1.2 mm | Flexible yet durable |

| Occlusal Rests | 1.0 mm | 1.2 - 1.5 mm | 2.0 mm | Sufficient for occlusal forces |

| Lingual Bar | 1.5 mm | 2.0 - 2.5 mm | 3.0 mm | Half-pear shape for strength |

Ready for Precision BPS Frameworks?

Start your remote BPS framework project today. Upload your scans and receive a quote within 24 hours.